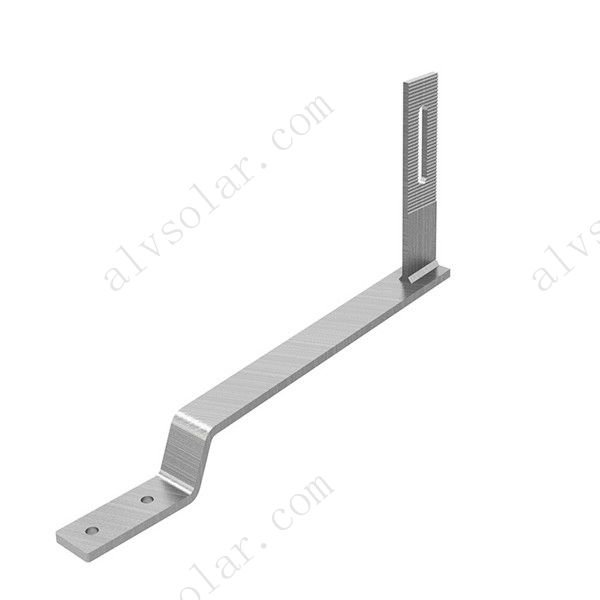

Solar Panel Mounting Washers Description

Solar panel mounting washers are critical components for ensuring the mechanical stability and structural integrity of solar mounting systems. These washers provide secure fastening by evenly distributing loads across surfaces, reducing stress concentration and preventing long-term damage to solar installations.

Used in both residential and commercial solar panel systems, these washers help maintain alignment, prevent loosening, and protect structural connections. Additionally, they are widely used in various industries including automotive, medical, marine, and industrial equipment that require effective load distribution and vibration resistance.

When choosing solar washers, it’s important to consider material compatibility, hole diameter, thickness, and surface treatment to ensure optimal strength and corrosion resistance in harsh outdoor environments.

Get a Quote

Features of Solar Panel Mounting Washers

Flat and Smooth Surface

Each washer is precision-crafted to feature a flat and burr-free surface, reducing the risk of panel damage and enabling tight and reliable fastening.

High Strength and Load Bearing

Designed to endure high tensile and compressive forces, these washers resist deformation under stress and maintain stable support over time.

Standardized Hole Sizes

The round holes are manufactured to consistent specifications, allowing for precise alignment and easy installation within solar mounting systems.

Wide Range of Sizes

Available in sizes such as M3, M4, M5, M6, M8, M10, and more, our washers can be tailored to accommodate a variety of mounting systems and fastening requirements.

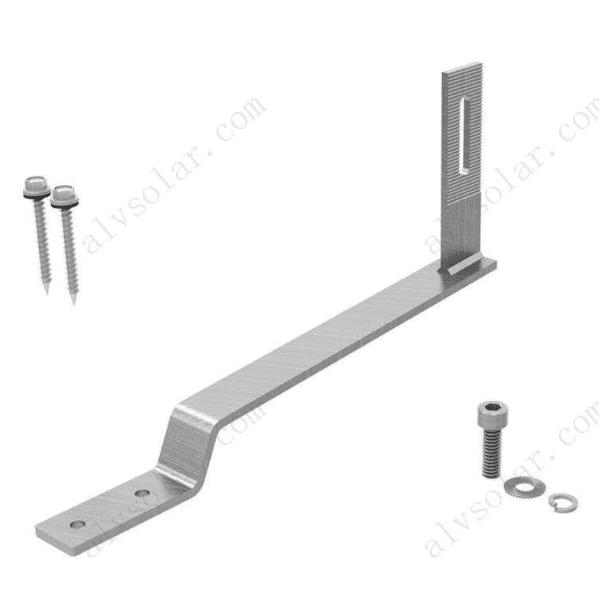

Flat Washers for Solar Panel Mounting

Flat washers are commonly used to evenly distribute fastener loads and prevent surface damage. They are ideal for solar racking and panel mounting due to their simplicity and reliability. Our flat washers are made from high-grade stainless steel for corrosion resistance, with optional materials such as carbon steel or nylon for specialized environments.

Available sizes include M3–M10 and beyond, with customizable finishes such as zinc plating, galvanization, or colored coatings.

Solar Panel Mounting Washers Specifications

| Washer Type |

Common Sizes |

Material |

Surface Treatment |

Application |

| Flat Washer |

M3, M4, M5, M6, M8, M10 |

Stainless Steel, Carbon Steel, Nylon |

Plain, Zinc-Plated, Galvanized, Custom Colors |

Solar Mounting, Industrial Fastening, Automotive |

| Spring Washer |

M3, M4, M5, M6 |

Stainless Steel, Carbon Steel |

Plain, Zinc-Plated |

Vibration-Resistant Mounting Applications |

| Serrated Lock Washer |

M3, M4, M5, M6 |

SS 304/316, Carbon Steel, Alloy Steel, Brass |

HDG, PTFE Coating, Plain, Galvanized |

Dynamic Load and Locking Systems |

Spring Washers for Solar Systems

Spring washers (split lock washers) provide resistance against loosening caused by vibration or dynamic loads. Their helical shape generates tension and friction that maintains tight connections under stress. Spring washers are ideal for use in wood, metal, and composite materials.

Serrated Lock Washers

Serrated lock washers offer superior anti-loosening performance even without high initial preload. With radial serrations that grip surfaces, these washers are perfect for systems subjected to vibration or movement. Available in stainless steel, alloy steel, and brass with various protective coatings.

Why Choose ALV as Your Solar Mounting Washer Supplier?

Customized Solutions

We offer full customization for washer materials, sizes, coatings, and packaging to meet specific project requirements in solar PV installations.

Eco-Friendly Manufacturing

Our commitment to sustainability includes green production practices and recyclable materials, contributing to long-lasting, energy-efficient solar systems.

Reliable Supply Chain

With strict quality control and fast delivery, ALV ensures consistent performance and timely support for your solar energy mounting hardware needs.

Solar Panel Mounting Washer FAQ

What Types of Washers Do You Offer?

We produce flat washers, spring washers, serrated lock washers, sealing washers, and custom-designed options for solar and industrial applications.

Which Materials Are Available?

Options include stainless steel (304, 316), carbon steel, brass, nylon, and various specialty alloys depending on the application.

Do You Offer Surface Finishes?

Yes, including plain, galvanized, zinc-plated, black oxide, and PTFE-coated finishes for increased corrosion resistance and visual appeal.

What Is the Minimum Order Quantity?

MOQ varies by washer type and size. Please contact our sales team for a quote based on your order volume.

Do You Provide Technical Data?

Yes, technical drawings, dimensional charts, and performance data sheets are available upon request.

What Quality Controls Are in Place?

We implement full inspection protocols and lab testing to meet international quality standards across all washer products.

Additional Information

What Is the Role of Washers in a Solar Panel Mounting System?

Washers help distribute load, prevent fastener loosening, absorb vibrations, and provide insulation against galvanic corrosion when dissimilar materials are used.

Why Is 304 Stainless Steel Sometimes Magnetic?

304 stainless steel is generally non-magnetic, but cold working or manufacturing-induced phase changes may cause slight magnetism.

Most Common Types of Stainless Steel:

- Austenitic: 304, 316 – excellent corrosion resistance.

- Ferritic: 430, 446 – magnetic with moderate corrosion resistance.

- Martensitic: 410, 420 – high strength and wear resistance.

- Duplex: 2205, 2507 – combines corrosion resistance and strength.

- Precipitation Hardening: 17-4PH, 15-5PH – heat-treatable high-strength grades.

How to Choose the Right Washer Size?

Match the washer’s inner diameter closely to the outer diameter of the bolt or screw to ensure optimal load distribution and secure fastening.

Can Washers Be Reused?

Flat washers may be reused if undamaged, while spring washers or serrated lock washers often lose effectiveness after use and should be replaced.

Contact Us

For pricing, samples, or custom specifications, submit an inquiry or reach out to our sales team.