C-Channel Steel Solar Panel Brackets

C-channel steel solar panel brackets offer strong structural support and optimal tilt angles to maximize solar power generation. Suitable for both residential and commercial solar installations, these brackets provide a durable and cost-effective solution for various solar energy systems.

Designed for long-lasting performance, C-shaped steel brackets are ideal for large-scale solar projects, delivering reliable stability while supporting clean, renewable energy output. Learn more about our solar mounting solutions.

Key Features of C-Channel Steel Solar Brackets

- Heavy-Duty Structural Support: Galvanized steel delivers exceptional strength and reliability in all weather conditions.

- Corrosion-Resistant Protection: Hot-dip galvanizing and anodizing protect against rust, even in coastal environments.

- Adjustable Tilt Angle: 0–60° adjustment to optimize sunlight exposure and energy conversion efficiency.

- Budget-Friendly Design: Steel is cost-effective and widely available, ideal for utility-scale projects.

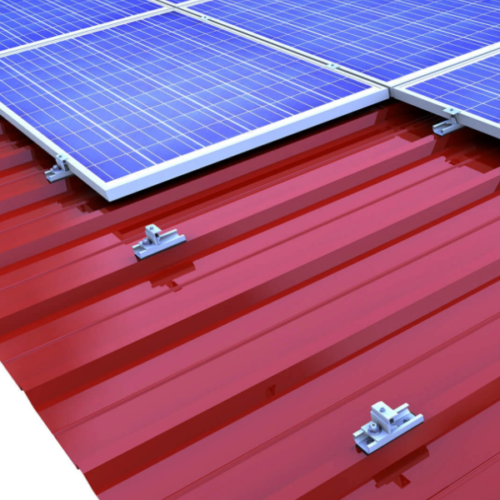

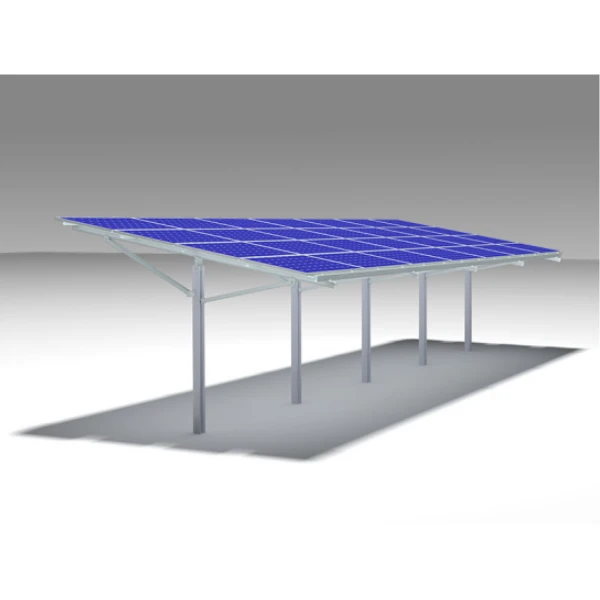

- Versatile Installation Scenarios: Compatible with ground-mounted systems, flat roofs, and carport structures.

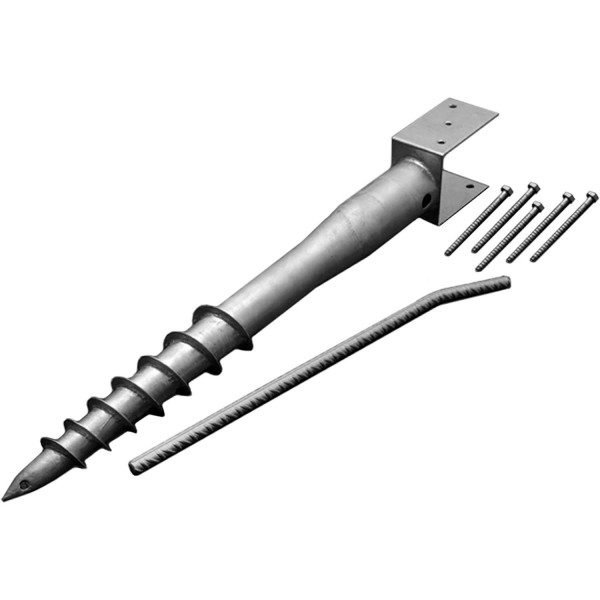

Mounting Foundation Options

- Concrete Foundation: Ideal for permanent and high-load-bearing installations.

- Ground Screw Piles: Eco-friendly, quick installation that reduces site preparation time.

Technical Specifications

| Installation Site |

Flat Roof, Ground, or Carport |

| Foundation |

Concrete or Ground Screw Pile |

| Material |

Q235B, SUS304, AL6005-T5 |

| Color |

Natural Silver or Customized |

| Corrosion Protection |

Galvanized Steel, Anodized Aluminum, Stainless Steel |

| Tilt Angle |

0–60° Adjustable |

| Wind Load |

<60M/S |

| Snow Load |

<1.4KN/m² |

| Standards |

AS/NZS 1170.2, JIS C 8955:2011 |

| Warranty |

10-Year Warranty, 25-Year Service Life |

Why Choose ALV for C-Channel Solar Brackets?

- Complete Manufacturing Solutions: From design to delivery, ALV provides full-service solar bracket solutions.

- Environmentally Responsible: Sustainable materials and processes for green energy compliance.

- Trusted Industry Partner: Global clients rely on ALV for quality, fast delivery, and technical support.

Frequently Asked Questions (FAQ)

What Packaging Methods Do You Use?

Long components are packed on steel pallets; small parts in cartons secured on plywood pallets.

What Is Your Average Lead Time?

Typically 20–30 days depending on order volume and customization. Contact our sales team for details.

What Payment Terms Are Available?

30% T/T in advance, remaining 70% before shipment for smaller orders.

Is There a Product Warranty?

Yes. 10-year warranty covering manufacturing defects and structural performance.

C-Channel vs. U-Channel Steel

C-Channel Steel is optimized for structural support applications such as beams and framing systems. U-Channel Steel is for general framing or aesthetic applications with lower structural support.

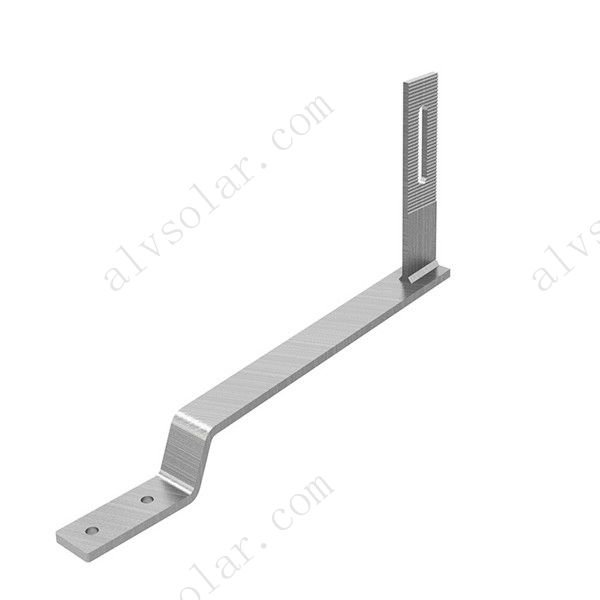

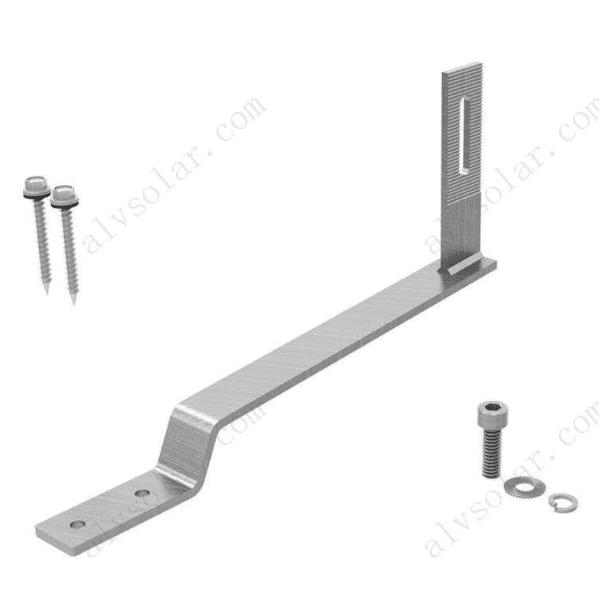

Installation Guide – How to Install C-Channel Solar Brackets

- Unpack Pre-assembled Structure: Inspect for completeness and damage.

- Fix to Ground: Align and anchor using ground screws or concrete footings.

- Install Rails: Attach horizontal support rails using bolts or clamps.

- Mount Solar Panels: Position and secure panels on rails.

- Secure All Connections: Tighten all bolts for stable support.

- Final Inspection: Check alignment, integrity, and safety compliance before commissioning.