How to Safely Install Solar Panels on Different Roof Types

Installing solar panels is a sophisticated engineering task that varies significantly depending on the architectural "bones" of your home. To ensure a system lasts its intended 25+ year lifespan without compromising the building's envelope, installation techniques must be tailored to specific materials.

Below is an expanded, technical deep-dive into safely installing solar arrays across diverse roofing substrates.

1. Pre-Installation: The Structural Audit

Before installation, a professional structural analysis is non-negotiable. Solar arrays add a "dead load" (the weight of the equipment) and a "live load" (wind and snow loads) to the structure.

Rafter Tracing: Use a high-quality stud finder or "tapping" method to locate the exact center of rafters. Missing a rafter and securing a lag bolt into just the plywood (sheathing) can lead to catastrophic failure during high winds.

The 10-Year Rule: If your roof material has less than 10 years of life remaining, replace the roof before the solar install. The cost of removing and reinstalling panels later far outweighs the cost of a proactive roof replacement.

2. Asphalt Shingle Roofs: The Flashing Priority

Asphalt shingles are the most common residential roof type. The primary risk here is water intrusion.

The "Water Shedding" Method: Never just "caulk" a bolt hole. Use a metal flashing plate that slides underneath the shingle row above the penetration. This ensures gravity carries water over the bolt, not into it.

Lag Bolt Precision: Use stainless steel lag bolts. Pre-drill pilot holes to prevent the wooden rafters from splitting, which could compromise the mechanical grip.

3. Metal Roofs: Non-Invasive Solutions

Metal roofs are often considered the "gold standard" for solar because they often outlast the panels themselves.

Standing Seam Roofs: These are ideal because you can use S-5! Clamps. These clamps grip the vertical seam of the metal roof without a single penetration. No holes means zero risk of leaks.

Corrugated/Trapezoidal Metal: These require "L-feet" brackets attached to the ribs. Always use EPDM rubber washers and specialized solar sealant (like M-1) that remains flexible across extreme temperature fluctuations.

Expansion & Contraction: Metal roofs move significantly with heat. Ensure your racking system allows for thermal expansion to avoid "creaking" sounds or stress on the solar cells.

4. Tile Roofs (Clay, Concrete, or Slate)

Tile roofs are notoriously difficult because tiles are brittle and cannot support a person's direct weight without cracking.

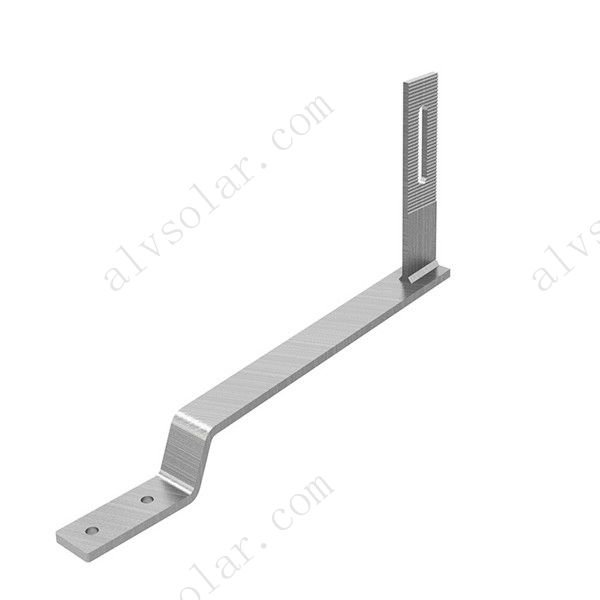

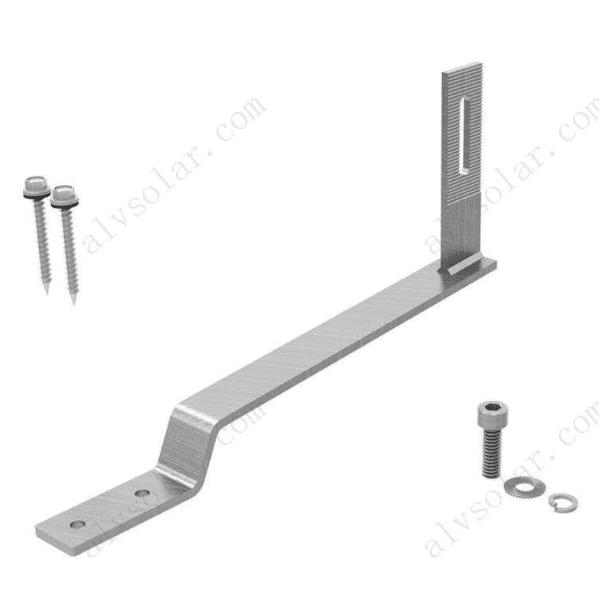

Tile Hooks vs. Replacement Mounts: * Tile Hooks: These contour around the tile to reach the rafter. You often need to "notch" or grind the bottom of the tile so it sits flush over the hook.

Replacement Mounts: These are the safest option. You remove a tile and replace it with a metal flashing that has a built-in mounting post. It looks like a tile but acts as a heavy-duty bracket.

Walking on Tiles: Always walk on the "overlap" sections (the strongest point) or use walk-boards to distribute your weight.

5. Flat Roofs: Ballasted vs. Attached

Flat roofs (TPO, EPDM, or Built-up) offer a different set of challenges, primarily regarding wind uplift.

Ballasted Systems: In many cases, you can avoid roof penetrations entirely by using weighted blocks to hold the panels down. This is excellent for maintaining roof warranties.

Tilt Legs: To maximize efficiency, panels are usually mounted on 10° to 15° tilt legs. This also assists with "self-cleaning" as it allows rainwater to wash away dust.

6. Critical Safety Protocols

Safety isn't just about a harness; it's about a systematic approach to the environment.

Fall Protection: A full-body harness must be tethered to an OSHA-approved roof anchor. The "swing fall" radius must be calculated to ensure you won't hit the ground or an obstacle if you slip.

Material Handling: Use a mechanical lift or a pulley system for panels. Carrying a 40lb, 2-meter-wide "sail" up a ladder in even a light breeze is extremely dangerous.

Rapid Shutdown Requirements: Modern codes (like NEC 2020) require a "Rapid Shutdown" switch. This ensures that in the event of a fire, first responders can de-energize the DC wiring on the roof to safe levels (under 30V) within seconds.

7. Electrical Integration

The transition from DC (panels) to AC (home) involves high voltages that require respect.

MC4 Connectors: Ensure all connections are fully seated (you should hear a "click"). Loose connections are the leading cause of solar fires due to electrical arcing.

Grounding (Bonding): Every metal component of the racking system must be grounded to provide a path for lightning or surges to safely reach the earth.