Qu'est-ce qui rend un système de montage « rapide à installer » ? – Design Insights

In solar projects, time is money — and a lot of it. Whether you’re installing a small rooftop system or a large solar farm, one of the biggest hidden costs is labor time. That’s why more and more installers, EPCs, and developers are looking for quick-to-install solar mounting systems. A system that can shave hours — or even days — off the job can mean higher profits, faster turnaround, and fewer errors.But what exactly makes a mounting system fast to install? Is it just about using fewer bolts? Or are there deeper design factors involved?

In this blog, we’ll break down the key design features and engineering insights that make a solar mounting system truly fast and efficient to install — without compromising safety or long-term reliability.

The Importance of Fast Installation in Solar Projects

Before diving into the design, let’s understand why installation speed matters so much:

1. Labor Costs Are Rising

In many countries, labor can account for up to 30% of the total solar system cost. Reducing installation time directly reduces costs, especially in high-wage regions.

2. Tight Project Deadlines

Large commercial and government projects often come with strict timelines. A delay in mounting means a delay in wiring, inspection, and commissioning.

3. Skilled Labor Shortages

In emerging markets, there's often a shortage of trained solar installers. A system that is simple and intuitive reduces the need for expert labor.

4. Weather Windows

In some locations, installers may only have short windows of time due to rain, snow, or extreme heat. Quick installation systems allow more work to be completed safely within limited timeframes.

A well-designed solar mounting system addresses all these challenges through smart engineering — and that brings us to the core question: what makes a system "quick to install"?

Key Features That Make a Mounting System Quick to Install

Not all mounting systems are created equal. Some are bulky, complex, or require on-site modifications. Others are designed with speed and simplicity in mind. Let’s look at the top five design features that define a fast-install solar structure:

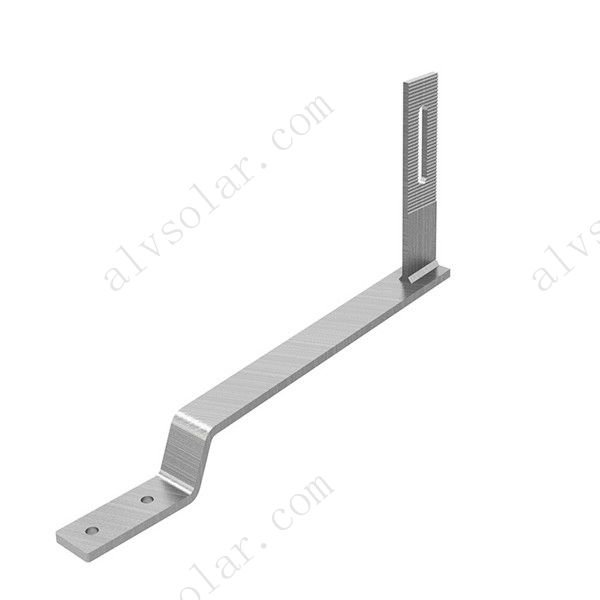

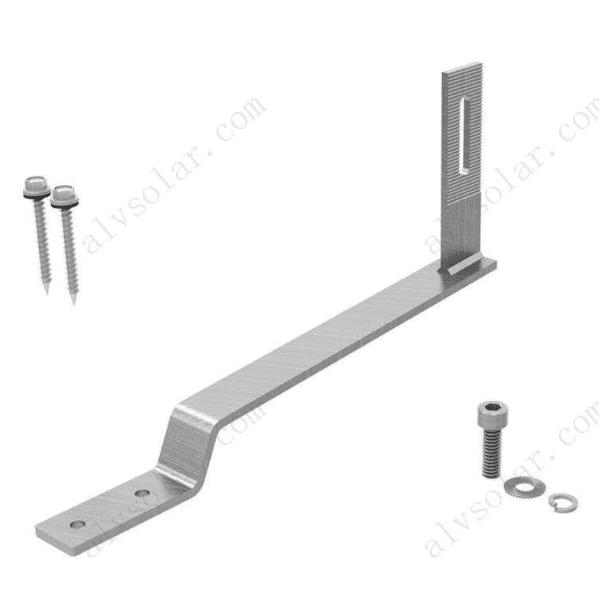

1. Pre-Assembled Components

One of the biggest time-saving elements is using pre-assembled parts. This means:

Rails already cut to length

Brackets with pre-installed bolts

Clamps that don’t require washers or separate pieces

Legs or triangle supports that come as single units

This reduces the number of steps needed on-site. Workers don’t need to hunt for hardware or follow complicated diagrams — they simply unpack and install.

2. Click-In or Snap-Fit Connections

Modern racking systems use smart connection designs such as:

Click-in rails

Snap-fit mid clamps

Push-and-turn locking bolts

These eliminate the need for wrenches, torque settings, or time-consuming alignment. Click-in components align themselves et lock securely, minimizing installation errors and improving safety.

This is especially helpful on sloped roofs or remote areas where installer movement is limited.

3. Modular and Repetitive Design

A modular design means the same parts can be used again and again:

Same rails for different rows

Universal clamps for different panel brands

Standard brackets for various roof types

This reduces the number of SKUs you need to stock, simplifies training for new staff, and ensures faster repetition on-site.

For example, if you’re installing a 200 kW system with 400 modules, and all rows use the same 3 components, you’ll move much faster than if every section has different bolts or angles.

4. Integrated Grounding or Fewer Tools Required

Some systems integrate automatic grounding into the clamps, removing the need for separate copper wires and bonding washers. Others use single-tool installation, where one hex key or torque wrench can complete the full structure.

This saves time on both:

Mechanical installation

Electrical grounding and inspection

And fewer tools also means less risk of missing hardware, injuries, or damage to components.

5. Clear Installation Manuals and CAD Drawings

Even the best system won’t install quickly if your team can’t understand it. A supplier should offer:

Simple, step-by-step manuals

Exploded-view drawings

Video guides

On-call support if questions arise

Better documentation helps reduce errors, misalignment, and rework — all of which cost time and money.

À Xiamen Al Import & Export Co., Ltd., we provide full technical support packages for every project.

Final Thoughts: Speed Is a Design Strategy, Not Just a Bonus

A truly “quick-to-install” solar mounting system isn’t built by chance. It’s the result of:

Smart design

Thoughtful engineering

Real-world installer feedback

Whether you’re working on rooftops, ground-mounted farms, or solar carports, saving time means saving money — and reducing the risk of mistakes or delays.

To recap:

Look for pre-assembled kits, click-in connections, et modular parts

Use suppliers that provide clear documentation and technical support

Always balance installation speed with safety and long-term reliability

If you’re planning your next solar project and want to install faster without cutting corners, reach out to Xiamen Al Import & Export Co., Ltd. today. Our quick-to-install mounting systems are designed to deliver efficiency, durability, and value from day one.

All Rights Reserved. Xiamen Al Import & Export Co., Ltd.