Using Ground Screws for Uneven Terrain Solar Projects

Solar projects often face many challenges when installed on uneven terrain. Hills, slopes, and rocky or sandy soils make traditional concrete foundations difficult and costly to install. Ground screws have become a popular and effective solution for mounting solar panels in such conditions. They offer flexibility, speed, and sustainability, making them ideal for uneven terrain solar projects. This article explains why ground screws are a great choice, how they are installed, and what benefits they bring to solar developers.

Advantages of Ground Screws on Uneven Terrain

The foundation is critical to the stability and longevity of solar ground mounting systems. In uneven terrain areas like mountains or rolling hills, concrete foundations require extensive excavation and curing time, which increase costs and environmental impact. Ground screws avoid many of these issues.

Ground screws can be mechanically screwed into various soil types, including clay, sand, and rock. Their design allows for adjustment in length and diameter, enabling a strong hold in diverse and complex soils. This adaptability ensures secure installation even when the terrain is irregular.

Installation is fast and clean. Since there is no need for large holes or concrete pouring, soil disturbance is minimized and vegetation damage is limited. The mechanized installation reduces labor and equipment costs, shortening project timelines.

Moreover, ground screws are reusable and removable. If a project needs to be relocated or upgraded, ground screws can be unscrewed and reused, reducing waste and supporting sustainable practices.

Installation Process and Technical Considerations

Proper installation of ground screws requires thorough planning and execution. First, a detailed site survey assesses soil conditions, load capacity, and terrain profile. This data informs the design of screw placement and size to distribute solar panel loads evenly.

Next, specialized machinery rotates the ground screws into the earth to the required depth and angle. This quick process can install many screws efficiently without heavy excavation.

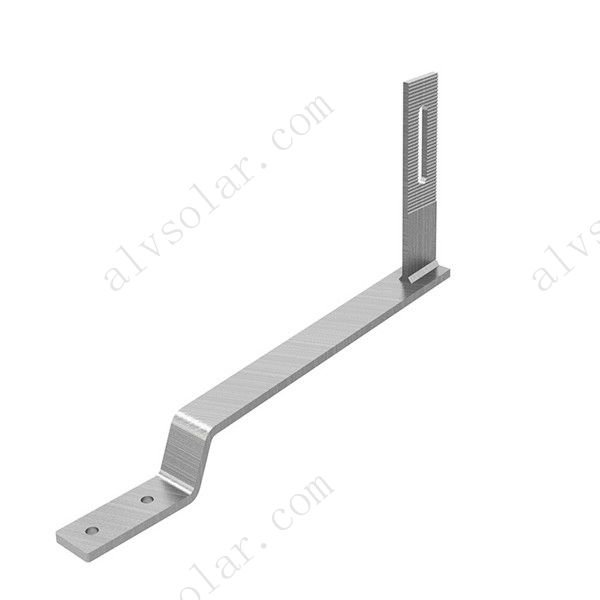

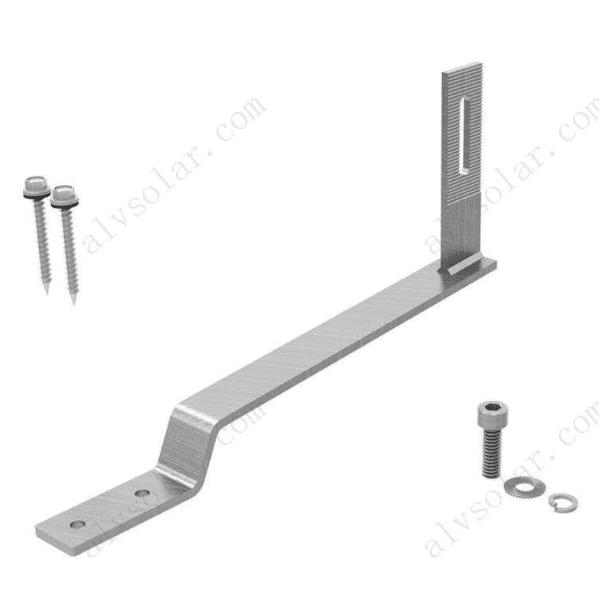

Once the screws are in place, mounting rails and brackets are attached using compatible hardware such as clamps and bolts. On uneven terrain, adjustable brackets and rails help achieve the optimal tilt and alignment for solar panels.

Finally, quality checks ensure the foundation’s strength and durability. Routine maintenance helps monitor corrosion and structural integrity, ensuring a long service life.

The Impact of Ground Screws on Solar Development

As solar energy demand grows, developing projects on challenging land becomes necessary. Ground screws open up new possibilities by allowing solar installations on slopes and difficult soils that were previously uneconomical.

They help maximize land use, reducing the need to clear flat land or disrupt ecosystems. This contributes to more sustainable solar deployment.

Financially, ground screws reduce upfront costs by eliminating concrete and shortening construction time. They also lower maintenance expenses, improving the overall return on investment.

Environmentally, ground screws limit soil disruption and can be removed with minimal impact at the end of the project life.

In summary, ground screws provide a flexible, efficient, and eco-friendly foundation for solar projects on uneven terrain. Xiamen Al Import & Export Co. Ltd. offers quality Solar Mounting Systems designed to work seamlessly with ground screws to meet diverse project needs worldwide. Contact us for professional advice and reliable products to make your solar projects succeed.

Xiamen Al Import & Export Co. Ltd. All Rights Reserved.