Как долго служат системы крепления солнечных батарей и подвержены ли они ржавчине?

When investing in a solar energy system, most people focus on the solar panels and inverters. However, the long-term performance and safety of any solar installation depend just as much on the structural support system: the solar mounting system. While panels typically come with a 25-year warranty, a critical question arises — how long does the mounting system last, and does it rust over time? These are not just technical details; they directly affect the durability, safety, and return on investment of a solar project.In this article, we’ll dive deep into the real-world lifespan of solar mounting systems, whether rust is a concern, and how to select the right materials for long-lasting performance.

The Lifespan of a Solar Mounting System: Designed to Last Decades

A well-designed and properly installed solar mounting system can easily last 25 years or more, matching or even exceeding the lifespan of solar panels. The actual service life depends on several factors:

Material quality

Manufacturing process

Installation environment (climate, wind, salt, etc.)

Maintenance practices

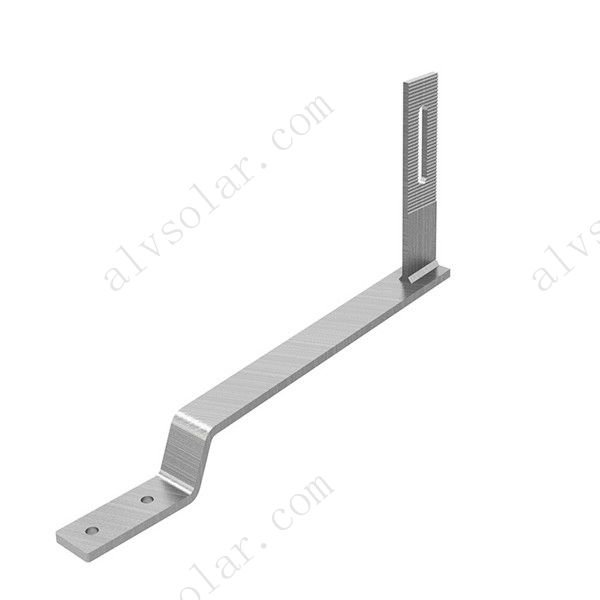

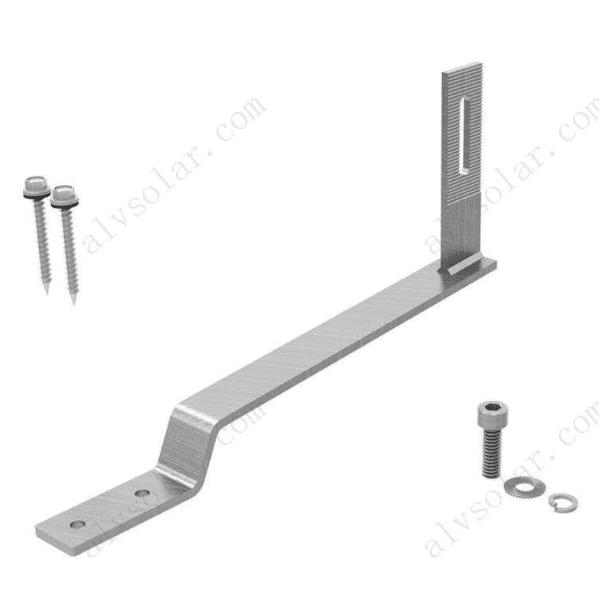

Most modern solar racking systems are engineered using either aluminum alloys (such as 6005-T5) or hot-dip galvanized steel (like Q235B). Both materials are chosen specifically for their mechanical strength и long-term outdoor durability.

For example, anodized aluminum mounting systems used in residential rooftops or carports are known for maintaining their structural integrity for over 25 years, thanks to their natural corrosion resistance and light weight. Galvanized steel structures, more common in ground-mounted solar farms, are engineered to resist environmental wear for even longer — sometimes 30 to 40 years, depending on coating thickness and site conditions.

Of course, the system’s longevity also depends on the engineering behind it. A structurally sound design that considers local wind speeds, snow loads, and thermal expansion ensures the system will stand the test of time without bending, cracking, or loosening.

Manufacturers like Xiamen Al Import & Export Co., Ltd. ensure every mounting system is subjected to environmental testing and quality control during production. With proper design and quality assurance, your mounting system becomes a long-term, low-maintenance asset.

Is Rust a Problem for Solar Mounting Systems?

The short answer is no — not if you use the right materials and coating technologies. Rust or corrosion is a natural enemy of any outdoor metal product, but in the solar industry, this challenge has been largely overcome through smart engineering and material science.

Here’s how corrosion is avoided in modern systems:

1. Aluminum Solar Mounting Systems

Aluminum, especially anodized types, forms a natural oxide layer that protects it from corrosion. This makes it ideal for rooftops, carports, and coastal installations. Unlike steel, aluminum does not “rust” in the traditional sense. It may oxidize over time, but the oxidation forms a stable protective layer rather than breaking down the metal.

Bonus benefit: Aluminum is lightweight, easy to install, and recyclable.

2. Galvanized Steel Mounting Systems

Steel is stronger and more cost-effective than aluminum in large-scale projects, but raw steel rusts quickly. To solve this, manufacturers use hot-dip galvanization, which coats the steel with a protective layer of zinc. The thickness of this coating determines how long it can resist corrosion.

For example, a hot-dip galvanized steel bracket with 80 microns of zinc coating can withstand over 20 years in outdoor conditions. In especially harsh environments (like coastal regions with salty air), steel components can be additionally treated with powder coatings or polymer layers to extend corrosion resistance.

3. Stainless Steel Components for Critical Areas

For small parts such as bolts, nuts, or grounding clips, stainless steel is often used due to its exceptional corrosion resistance. These components ensure the long-term stability of joints and contact points.

It’s also worth noting that system design plays a crucial role in avoiding corrosion. Poor water drainage, metal-on-metal contact without insulation, or incorrect installation can lead to premature rust, even with good materials. That’s why proper engineering, spacing, and insulation are essential parts of the design process.

In short, if you choose a reputable supplier who uses certified materials and you follow correct installation guidelines, rust should not be a concern in your solar project.

Choosing the Right Mounting Material: Performance vs. Cost

Now that we understand the durability and corrosion resistance of solar mounting systems, how should you choose between aluminum and steel?

When designing a project, consider the environmental conditions, budget, ease of transport, и labor cost. For example:

For residential rooftops or coastal installations, anodized aluminum is usually preferred due to its corrosion resistance and low weight.

For utility-scale ground systems, hot-dip galvanized steel is typically the go-to choice because it provides excellent mechanical strength and is more cost-effective on a large scale.

A professional supplier like Xiamen Al Import & Export Co., Ltd. can provide tailored recommendations, engineering drawings, and technical support based on your project’s specific needs.Remember, a high-quality solar mounting system is not an afterthought — it is the backbone of your solar investment. Whether you are installing solar panels on a home, a commercial rooftop, or a large solar farm, the right structure ensures your panels perform optimally for decades without the risk of structural failure or corrosion.