Zemin Montaj Sistemlerindeki Yenilikler: Daha Hızlı Kurulum ve Gelişmiş Dayanıklılık

The solar industry is advancing rapidly, and with it, the technology behind ground mounting systems is evolving to meet growing demands. Large-scale solar projects require mounting solutions that not only support heavy panels reliably but also can be installed quickly and withstand harsh environmental conditions over many years. Recent innovations in ground mounting systems have focused on accelerating installation processes, improving material durability, and optimizing designs to reduce costs and boost project efficiency.

In this article, we explore these key innovations and how they are transforming the way solar farms are constructed and maintained.

Modular Design: Revolutionizing Installation Efficiency

A standout innovation in ground mounting systems is the widespread adoption of modular design principles. Traditionally, mounting structures involved many on-site fabrication steps — cutting rails, welding frames, and assembling custom parts — which slowed down installation and increased labor costs. Modular systems change this by offering standardized, prefabricated components ready for quick assembly.

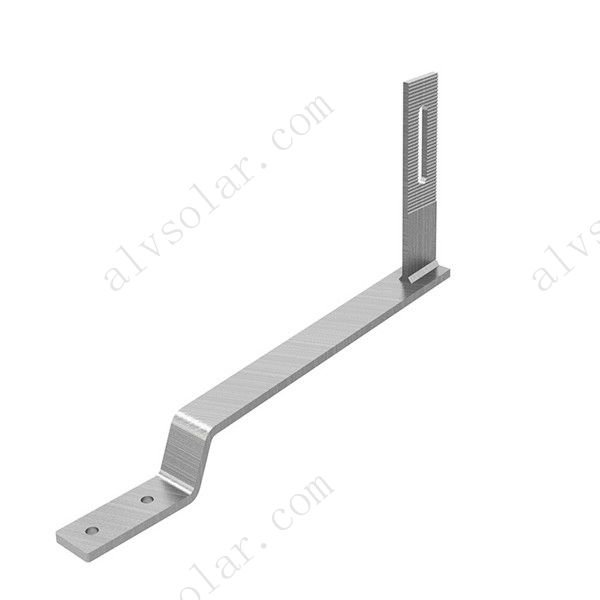

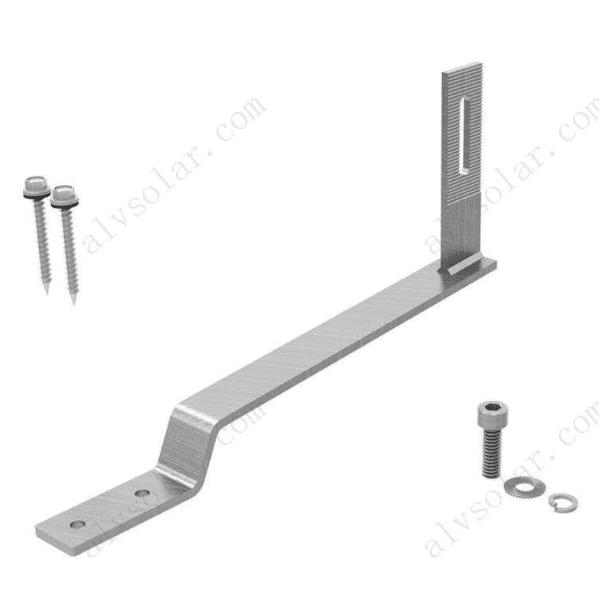

Modular parts such as pre-cut rails, universal clamps, adjustable brackets, and pre-drilled fittings can be efficiently transported and quickly assembled like building blocks. This standardization greatly reduces on-site customization and errors. It also enables installation teams to work faster with fewer specialized tools or skills, which is especially beneficial in remote or challenging locations.

Moreover, modular systems provide flexibility and scalability. Developers can easily adjust the number of mounting units to fit projects of various sizes without redesigning the entire system. This adaptability reduces engineering time and speeds up procurement.

Logistically, modular components simplify transportation and storage. Lightweight and uniform parts can be packed densely, reducing freight costs and environmental impact.

The net effect of modular design is significant time savings on-site. Projects that might have taken weeks to complete can now be finished in days, accelerating energy production and improving return on investment.

Material Advances for Long-Term Durability

Materials technology has also progressed, addressing common issues such as corrosion, mechanical wear, and structural fatigue that have traditionally limited the lifespan of mounting systems.

Galvanized steel remains a workhorse material due to its strength and affordability. However, enhanced galvanization methods — like hot-dip galvanization combined with polymer overlays — have greatly improved corrosion resistance. These treatments protect steel from rust even in highly humid or saline environments, such as coastal solar farms.

Aluminum alloys are increasingly popular for their inherent corrosion resistance and lighter weight. Advances in alloy composition and manufacturing now produce aluminum mounts with strength comparable to steel but with easier handling and lower transportation costs. Aluminum’s natural oxide layer prevents rust, making it ideal for locations with high moisture or salt exposure.

In addition to metals, some manufacturers incorporate composite materials and specialized powder coatings that resist UV radiation, chemical exposure, and abrasion. These treatments extend the system’s operational life, reduce maintenance needs, and preserve appearance.

Selecting the right material and surface treatment is critical for ensuring mounting systems can withstand years of environmental stress — from heavy winds and snow to extreme temperatures and corrosive pollutants.

Innovative Installation Techniques and Tools

Installation methods have evolved in parallel with design and material improvements, further speeding up deployment and enhancing quality.

One of the most transformative installation innovations is the use of ground screws instead of traditional concrete foundations. Ground screws are mechanically driven deep into the soil with specialized equipment, providing immediate load-bearing support without the need for excavation, formwork, or concrete curing.

This method dramatically reduces installation time — often by weeks — and minimizes site disturbance, preserving soil and reducing environmental impact. Ground screws can be used on various soil types, including rocky or uneven terrain, offering flexibility for diverse project sites. Their reusability also aligns with sustainable construction practices.

Pre-assembled racking and rail systems complement ground screws by arriving on site ready for quick assembly. These kits reduce manual cutting or fitting, lowering error rates and ensuring uniform structural integrity.

Digital tools also aid modern installation. Laser-guided alignment devices help crews position rails and panels with millimeter precision, improving system performance and reducing rework. Mobile apps and project management software allow real-time monitoring of installation progress, resource allocation, and quality control.

Collectively, these techniques enable safer, faster, and more accurate installations, lowering labor costs and speeding the path to project commissioning.

These innovations in ground mounting systems are driving a new era of solar project development, delivering tangible benefits to all stakeholders. Faster installations translate to quicker revenue generation and lower labor expenses. Enhanced durability reduces lifecycle costs and maintenance burdens. Improved modularity and materials increase design flexibility and environmental resilience.

At Xiamen Al İthalat ve İhracat Ltd. Şti., we integrate these cutting-edge innovations into our Solar Mounting Systems to support your project’s success. Whether you’re building in challenging terrain or harsh climates, our solutions offer reliable performance, installation efficiency, and long-term value.

Contact us today to explore how our advanced ground mounting systems can accelerate and strengthen your next solar installation.

Xiamen Al Import & Export Co. Ltd. All Rights Reserved.