Maintenance Tips for Long-Lasting Ground-Mounted Solar Systems

Ground-mounted solar systems are an excellent way to maximize energy production while keeping your panels accessible for maintenance. Unlike roof-mounted systems, ground-mounted setups allow easier cleaning, inspection, and adjustments. However, like any technology, regular maintenance is key to ensuring your system performs efficiently for years. Here are essential tips to keep your ground-mounted solar system in top shape.

1. Regular Cleaning of Solar Panels

Dust, dirt, bird droppings, and pollen can accumulate on panels over time, reducing their efficiency. Cleaning panels every few months—or more often in dusty areas—can significantly improve energy output. Use:

Soft brushes or sponges

Mild soap and water

Avoid high-pressure washers that could damage the panels

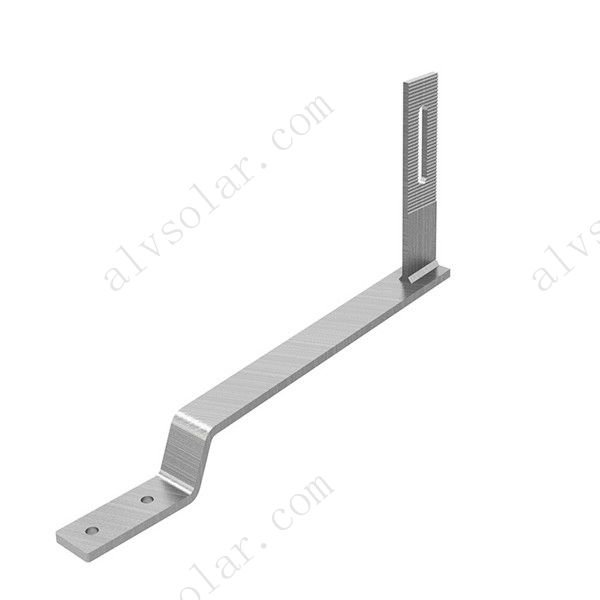

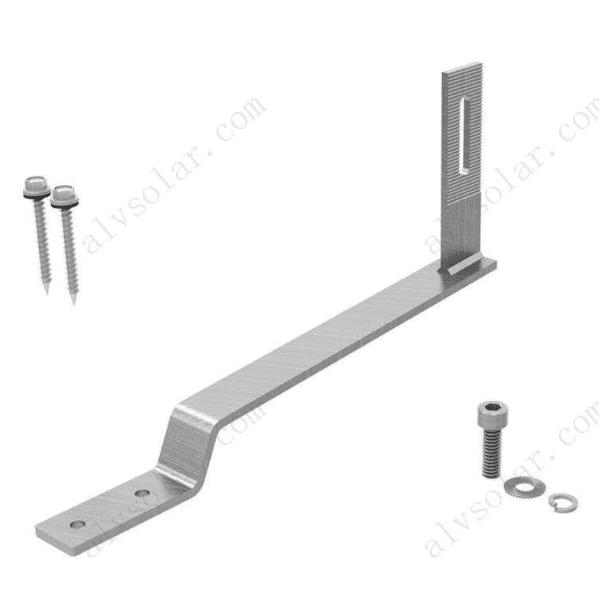

2. Inspect Mounting Structures

Check the ground mounts, bolts, and clamps periodically for signs of corrosion, looseness, or wear. Make sure the structure remains sturdy, especially after storms or heavy winds. Tighten loose bolts and replace any rusted parts to prevent structural issues.

3. Monitor Electrical Connections

Inspect wiring, inverters, and junction boxes regularly. Look for:

Loose connections

Signs of wear or damage

Rodent or pest interference

Properly secured and insulated connections prevent energy loss and reduce the risk of electrical faults.

4. Maintain Surrounding Area

Keep the area around your ground-mounted system clear of tall grass, weeds, or overhanging branches that could cast shadows on your panels. Regular landscaping ensures maximum sunlight exposure and reduces the risk of damage from falling debris.

5. Seasonal Tilt Adjustments

If your system uses adjustable mounts, change the tilt angle seasonally to optimize sunlight capture. Fixed systems may not allow adjustment, but keeping panels at the optimal angle whenever possible improves overall efficiency.

6. Check for Tracking System Functionality

For systems with single-axis or dual-axis trackers, ensure the motors and tracking mechanisms are operating smoothly. Lubricate moving parts as recommended by the manufacturer and inspect sensors for any obstructions.

7. Monitor System Performance

Use monitoring software to track energy production. Sudden drops in performance can indicate panel shading, dirt accumulation, or electrical issues. Early detection allows timely intervention before minor problems become major.

8. Professional Inspection

Even with regular self-maintenance, consider having a professional inspection every 1–2 years. Professionals can spot potential issues that may not be obvious, such as foundation settling or subtle electrical problems.